HPP Pump Control Press Brake

HPP machine is oil-electric hybrid pump-controlled bending machine, following European design style to ensure high precision;

·Quickest working speed with silent running and High accuracy

·Excellent energy saving effect, compared with the traditional bending machine hydraulic system, energy saving over 70%;

·Electricity consumption is greatly reduced, and carbon emissions are correspondingly reduced; The tank volume is reduced, reducing the cost; Low heat balance temperature, saving cooling installation, prolonging the life of hydraulic components;

·Improved safety and economy, servo motor braking faster than ordinary motor, emergency pressure, flow cutting fast;

·Strong anti-biased load, high synchronization accuracy;

Features:

·Delem DA-53T touch screen controlling system from Holland controls the backgauge, bending depth and the compensation of the crowning accurately. This is designated as Y1, Y2, X & Crowning axis (V).

·Crowning table adopt LVD type adjustable crowning, to ensures the ram and table are parallel during the bending operation.Crowning system is with many tapered wedges through accuracy machining, no need any maintenance, no oil leakage, it maintains original machining accuracy all the machine life.

·X aixs use Aluminium Alloy for back gauge cross beam, it is of solid moulded casting. Featuring light weight and reliability.No deformation after long time running due to very few internal stress.

Optional:

·Delem DA-66T touch screen graphical CNC control

·Delem DA-69T 3D graphical CNC control

·Manual quick clamp tool holders

·Wila tool holders in manual or hydraulic clamping configuration for quick tool changes

··3 Color indicator Front/back lighting

··DSP laser protection

Multi-axis back gauge configuration options

·CNC R axis

·X prime finger

·X1, X2, R

·X, R, Z1, Z2

·X, X prime, R, Z1, Z2

·X1, X2, R, Z1, Z2

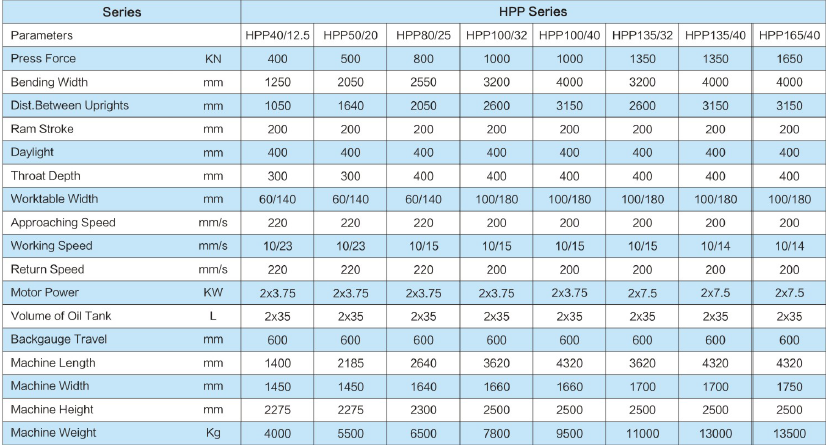

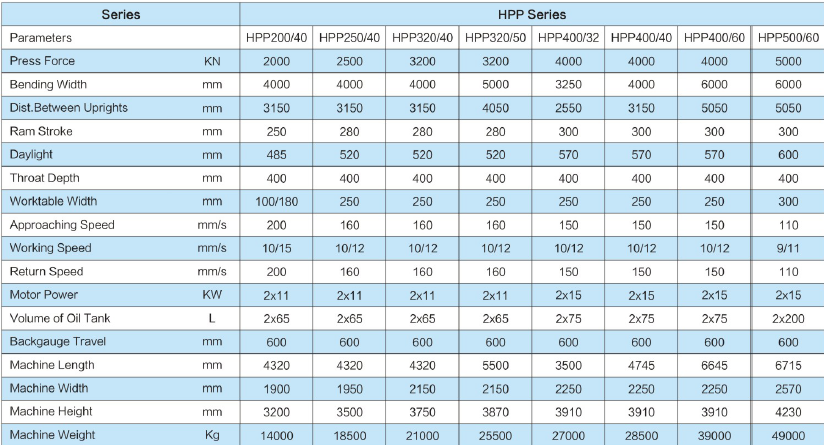

HPP Technical parameters: